METAL MACHINING & PROCESSING

‘DSPL Tools’ innovative platform enables seamless manufacturing of metal components, from prototypes to large-scale production. Our team specializes in the design, development, and precision manufacturing of high-quality metal parts. With over 30 years of expertise in CNC machining, wire bending, stamping, milling, welding, and more, our engineers provide comprehensive Design for Manufacturability (DFM) feedback to ensure efficient, hassle-free production. Our platform offers one-click access to inspection reports and material test certificates, along with a range of finishing and post-processing options for complete, end-to-end manufacturing solutions’

END TO END METAL MANUFACTURING

High quality, tight tolerance CNC machined components with high scalability for diverse applications across industries.

CNC TURNED COMPONENTS

DSPLTools’s CNC turning services helps you in manufacturing intricate CNC turned components with high precision for different materials.

CNC Turned Components

DSPLTools’s CNC turning services helps you in manufacturing intricate CNC turned components with high precision for different materials.

DSPLTools’s CNC turning services helps you in manufacturing intricate CNC turned components with high precision for different materials.

Whether you need turned parts for prototyping or full production runs, we have the capability to fulfil your requirements. Machines at our disposal are of the highest machining capability and can confirm to your stringent tolerance controls. Our competency in CNC turning include Turning centre, turn-mill centre and conventional lathe.

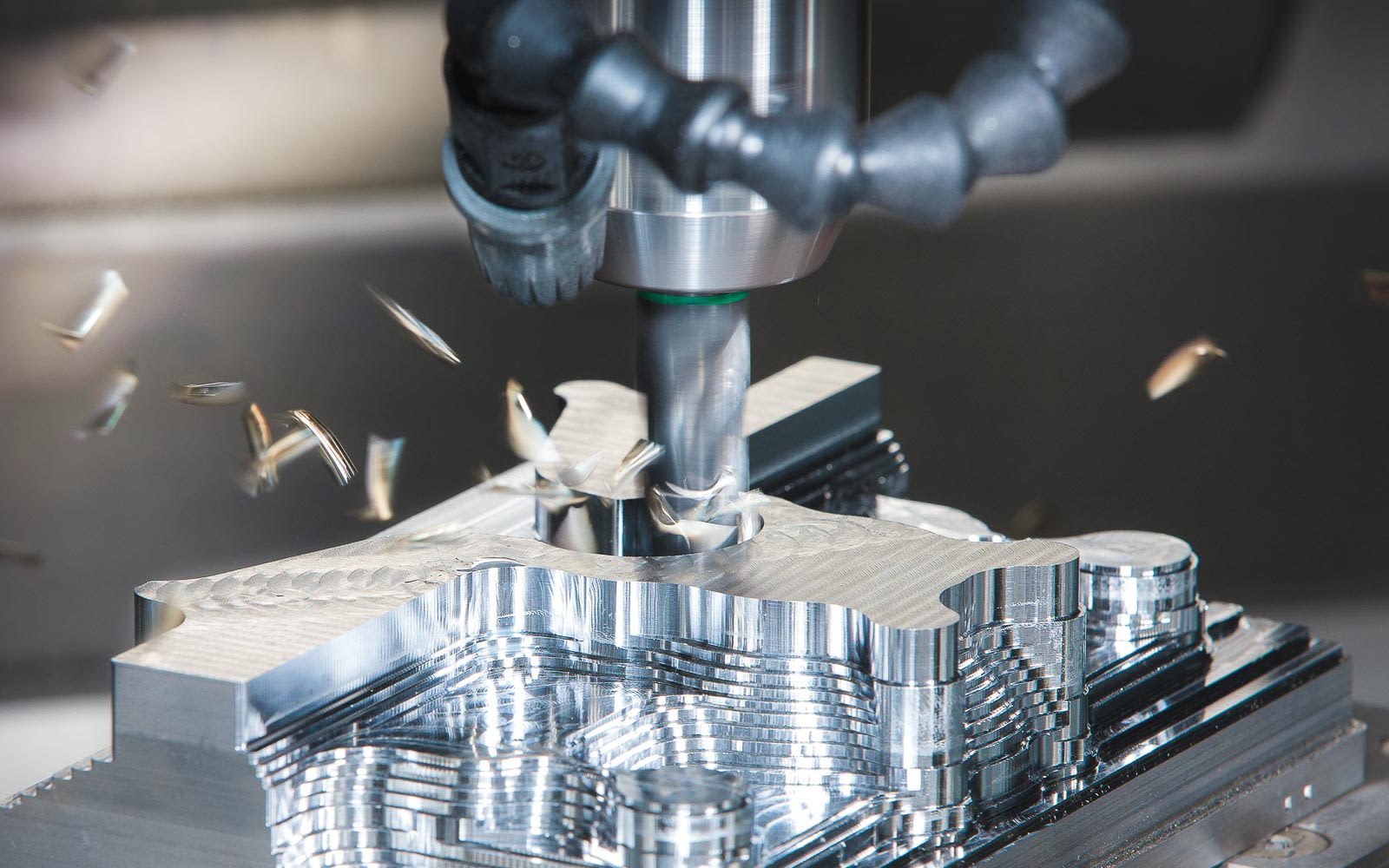

CNC MILLING SERVICES

DSPLTools’sCNC Milling Services are the perfect match for you to produce CNC machined components with high precision.

CNC Milling Services

DSPLTool’s CNC Milling Services are the perfect match for you to produce CNC machined components with high precision.

DSPLTool’s CNC Milling Services are the perfect match for you to produce CNC machined components with high precision.

Whether you need milled parts for prototyping or full production runs or for making moulds, we have the capability to fulfil your requirements. Our competency in CNC milling includes 3 axis, 4 axis, 5 axis machining centres and conventional milling, and based on your requirement, we can also manufacture for customized tolerances and with custom jigs and fixtures.

EDM

Wire EDM is an extremely high precision machining process and tolerances of up to 1 micron.

EDM

Wire EDM is an extremely high precision machining process and tolerances of up to 1 micron.

Wire EDM is an extremely high precision machining process and tolerances of up to 1 micron.

DSPLTools has the competency to fulfil all your needs with regards to Wire EDM as we can manage both for prototype and full production runs.

CNC WIRE BENDING

“DSPL TOOLS OFFERS COMPLETE SOLUTION FOR CNC & TRADITIONAL WIRE BENDING NEEDS FOR INTRICATE GEOMETRY, SHAPE & TIGHT TOLERANCES

Plastic machining

DSPLTools offers a complete solution for your plastic machining needs for different polymers, intricate geometries, and tight tolerance parts

DSPLTools offers a complete solution for your plastic machining needs for different polymers, intricate geometries, and tight tolerance parts

Plastic machining is chosen whenever we need to produce plastic parts for a small to medium scale production run and requires high structural strength. Machining plastics can also reproduce detailed features in the part (Like precise holes). The tolerances will be tighter compared to 3D printing. The mechanical properties of a machined plastic part are also much better than a 3D printed part even when using the same material.

METAL STAMPING

DSPL TOOLS OFFERS METAL STAMPING SOLUTIONS FOR SMALL TO LARGE SIZE APPLICATIONS

Grinding

Grinding is the process of using an abrasive tool to machine the parts to very precise dimensions.

Grinding is the process of using an abrasive tool to machine the parts to very precise dimensions.

DSPLTools can provide you with various types of grinding, that include creep feed grinding, centreless grinding, Cylindrical grinding and surface grinding. With grinding, you can get your parts accurate to within to 5 microns.

Why DSPLtools for CNC Machined Components ?

-

MULTIPLE MACHINING FACILITIES

-

ONE STOP MACHINING SOLUTION

-

UNLIMITED CAPACITY

-

CERTIFIED FACILITIES

-

TOLERANCES UPTO 5 MICRONS

-

COMPETITIVE AND PRICE MATCH GUARANTEE

-

PROPRIETARY SOFTWARE PLATFORM

-

MULTIPLE FINISHING OPTIONS

MULTIPLE PROCESSING AND FINISHING OPTIONS

Aluminium alloys

Aluminium is the most commonly used lightweight material, and it offers a high weight to strength ratio and good corrosion resistance properties. They also have exceptional machinability, workability and weldability, and so, they can be cast, machined, forged, fabricated, etc. It is very prevalent in Automotive, Aerospace, and Industrial applications.

Aluminium is the most commonly used lightweight material, and it offers a high weight to strength ratio and good corrosion resistance properties. They also have exceptional machinability, workability and weldability, and so, they can be cast, machined, forged, fabricated, etc. It is very prevalent in Automotive, Aerospace, and Industrial applications.

Copper alloys

Pure copper alloys like 101 or 110 have exceptional electric and heat conductivity. Because of that, it has high usage in manufacturing parts for electricals. Alloys of copper – Brass and Bronze – have high utility for both industrials and consumer products. They have great machinability and workability.

Pure copper alloys like 101 or 110 have exceptional electric and heat conductivity. Because of that, it has high usage in manufacturing parts for electricals. Alloys of copper – Brass and Bronze – have high utility for both industrials and consumer products. They have great machinability and workability.

Stainless steel alloys

Stainless steel is a type of steel that has around 11% of chromium. As the name suggests, stainless steel has high corrosion resistance. In addition to that, they have higher hardness, and when polished, has a great lustrous appearance. They have decent workability and weldability making them compatible with casting, machining, forging, fabrication, stamping, etc. Because of its corrosion resistance properties, it has found high applications in household products like cutlery, furniture and kitchen products, and industrial applications like automobiles, machine elements, etc.

Stainless steel is a type of steel that has around 11% of chromium. As the name suggests, stainless steel has high corrosion resistance. In addition to that, they have higher hardness, and when polished, has a great lustrous appearance. They have decent workability and weldability making them compatible with casting, machining, forging, fabrication, stamping, etc. Because of its corrosion resistance properties, it has found high applications in household products like cutlery, furniture and kitchen products, and industrial applications like automobiles, machine elements, etc.

Steel Alloys

Steel is among the most commonly used materials for both industrial and consumer applications. This is because steel offers great value; it is economical, has excellent machinability, workability, heat treatability, and has high strength. Steel is also among the most versatile materials out there as steel can be cast, machined, forged, fabricated, and more.

Steel is among the most commonly used materials for both industrial and consumer applications. This is because steel offers great value; it is economical, has excellent machinability, workability, heat treatability, and has high strength. Steel is also among the most versatile materials out there as steel can be cast, machined, forged, fabricated, and more.

Inconel & Special Alloys

Inconel and other special alloys like Monel, Hastelloy, Kovar and Invar, are materials with application-specific special properties like ultra-low thermal coefficient of expansion, Mechanical integrity at extreme temperatures, etc. They are generally more expensive and used only for niche applications.

Inconel and other special alloys like Monel, Hastelloy, Kovar and Invar, are materials with application-specific special properties like ultra-low thermal coefficient of expansion, Mechanical integrity at extreme temperatures, etc. They are generally more expensive and used only for niche applications.

Titanium Alloys

Titanium alloys have exceptional strength to weight ratio, can maintain its mechanical properties at elevated temperatures, and it is biocompatible too. These properties make it ideal for Aerospace and performance automotive applications. It is also one of the most common materials for making medical join replacements. They also have decent weldability, workability and machinability.

Titanium alloys have exceptional strength to weight ratio, can maintain its mechanical properties at elevated temperatures, and it is biocompatible too. These properties make it ideal for Aerospace and performance automotive applications. It is also one of the most common materials for making medical join replacements. They also have decent weldability, workability and machinability.

Machinable plastics

DSPLTools can help you manufacture your plastic machined components for the following plastics.

DSPLTools can help you manufacture your plastic machined components for the following plastics.